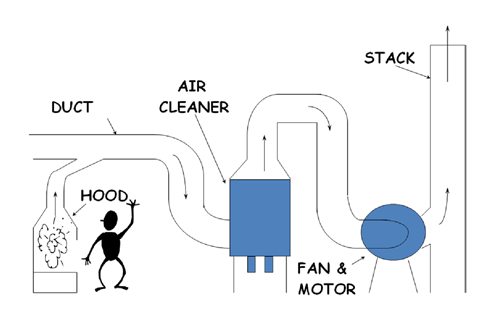

Isokinetic Stack Monitoring

Req : Department of Environment (Environment Quality – Clean Air Regulation 1978) Local Exhaust Vertilation Monitoring

Reg : 17 & 18 Department of Occupational Safety and Health (DOSH)

Noise Monitoring - DOE and DOSH Chemical Health Risk Assessment (CHRA) Regulation 9 of DOSH Ambient Air Monitoring

Req : Malaysian Recommended Env. Air Quality Guideline

Water Analysis (DOE Std A & B)

Refer to SAMM certificate No. 106

Traning

*All the chemical analysis is carried out by the SAMM’s accredited laboratory*

|